Alternative feedstock for a conscious product development

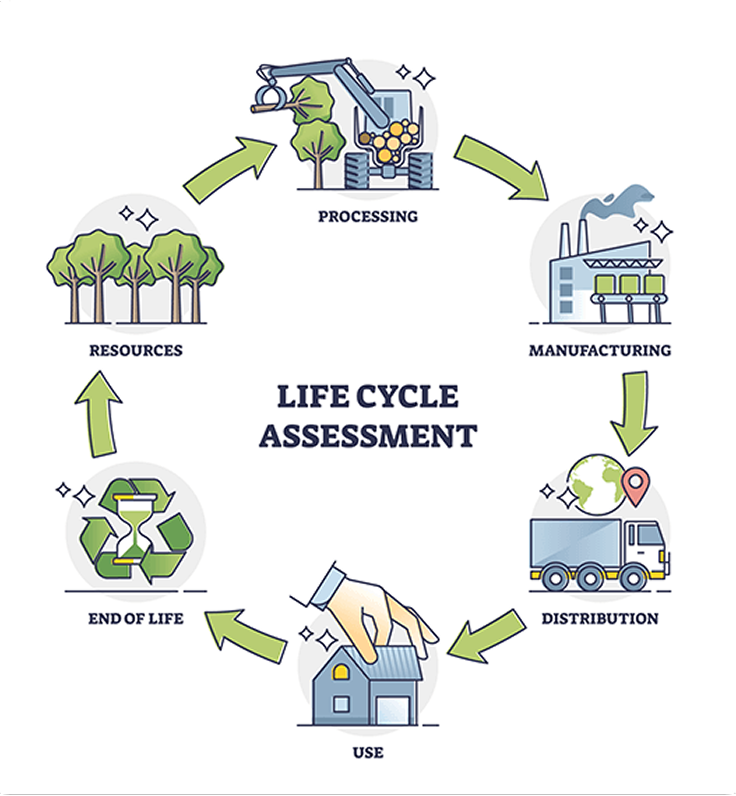

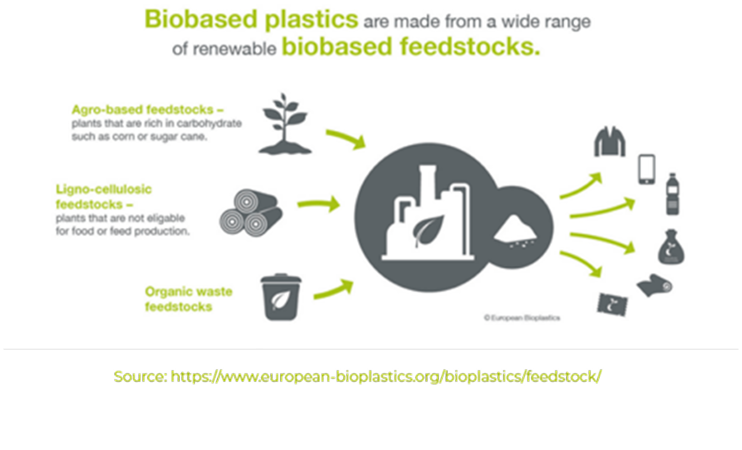

There are different feedstock options to produce biobased plastics. Trocellen Group does not promote the use of first generation feedstock as it is in direct competition with food production, instead preferring suppliers who are focusing on using second-generation feedstock, made of non-food biomass, whilst monitoring all upcoming alternative feedstock opportunities (other second and third generation feedstock).

Feedstock sourcing in the supply chain: sustainable, transparent, responsible and trusted

Trocellen Group’s responsibility is to ensure a supply chain where no possible negative impact can override the benefits of the usage of the biobased raw material product. Trocellen Group has set up its’ supplier engagement process to enable trusted communication with the key suppliers, to ensure, that our partners are working with the same motivation towards the creation of more sustainable products.

To ensure the transparency of the processes our plants where we produce TR-EECell products have International Sustainability and Carbon (ISCC) certifications.

We also we adopted the (3rd party) DIN CERTCO certification, in order to get stated what is the actual amount of that content of the specific TR-EEcell type, in the range of 20-50%, 50-85% or >85%.