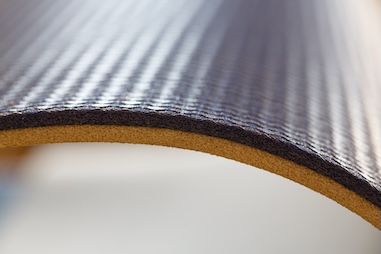

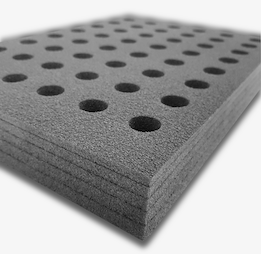

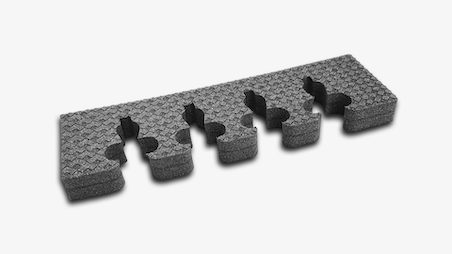

Heat lamination is a process for producing multi-layer products (these are called laminates), this allows us to combine the properties of the layers.

In case of PE foam we use only heat and some pressure to bond the two surfaces together, it means that no additional material is necessary. This is only possible if the two materials are „a bit similar” to each other chemically. If the material is too sensitive to heat (for example non-crosslinked PE foam or PS foam), we can’t process it this way.

Materials that we can laminate to our foam with heat lamination:

- Other cross-linked polyolefin foams

- LDPE, HDPE, PP films

- EVA films, certain other ethylene copolymer films

- Certain PU foams

- Certain textiles

- Certain papers

- Wood

We can simulate lamination in our laboratory and test the new materials, so if you have something in mind that is not on this list, we can test it and give you feedback or recommendation for alternatives.

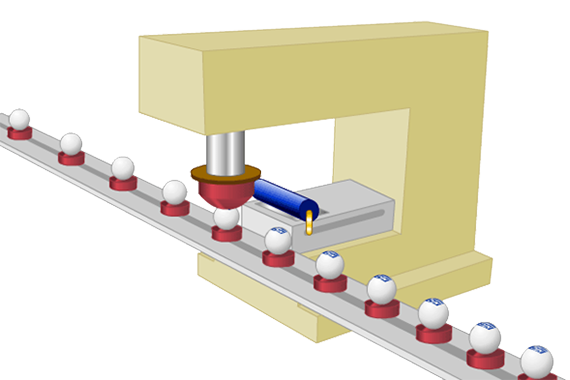

Heat lamination can be a continuous process, but a batch process too. For the continuous process around 20 mm is the maximum thickness that is possible. With the batch process it is possible to laminate lots and lots of layers on each other, so for example we can produce foam blocks with up to 500 mm thickness.